-

ProLink PL-PC-U6-1TQ UNSHIELDED CAT6 PATCH CORD W/ T568B WIRING, 1M, LSZH Turquoise

63,00 EGP63,00 EGP×

The Attributes of the Copper and Fiber Solutions in Network Cabling Systems

In the realm of network cabling systems, choosing between copper and fiber solutions is a critical decision that can significantly impact the performance, reliability, and scalability of an organization’s network infrastructure. Each solution has distinct advantages and considerations, making it essential to understand their differences to make an informed choice.

Here we can illustrate some of the core differences between the two cabling systems: _

- Transmission Speed

Copper Solution: Copper cabling, particularly Cat5e, Cat6, and Cat6a, typically supports speeds up to 1 Gbps, with Cat6a capable of reaching 10 Gbps over shorter distances. However, the speed of copper cabling diminishes significantly over longer distances due to signal attenuation and electromagnetic interference.

Fiber Solution: In contrast, fiber optic cables can support exceptionally high speeds, with single-mode fiber capable of reaching up to 100 Gbps and beyond. Fiber maintains consistently high performance over long distances with minimal signal loss, making it ideal for bandwidth-intensive applications.

- Distance

Copper Solution: The maximum distance for copper cabling is generally limited to 100 meters (328 feet) for Ethernet connections. Over longer distances, copper is prone to signal degradation and electromagnetic interference, which can affect data integrity.

Fiber Solution: Fiber optic cables, however, can transmit data over several kilometers without significant loss. Single-mode fiber can span distances up to 40 km or more, while multimode fiber can cover up to 2 km. This makes fiber a reliable choice for long-haul communications.

- Bandwidth

Copper Solution: Copper cabling offers limited bandwidth capacity, typically up to 10 Gbps with Cat6a cabling. It is also prone to crosstalk and electromagnetic interference, which can further affect bandwidth and data quality.

Fiber Solution: Fiber optic cables provide very high bandwidth capacity, capable of supporting multiple channels of data simultaneously. They are immune to electromagnetic interference, offering a cleaner and more stable transmission path.

- Installation and Flexibility

Copper Solution: Copper cabling is generally easier to install and terminate, with common tools and techniques widely available. Its flexibility and durability make it suitable for environments with frequent moves, adds, and changes.

Fiber Solution: Fiber installation is more complex, requiring specialized skills and tools for splicing and termination. Fiber cables are more delicate and susceptible to damage during installation and handling, necessitating careful management.

- Cost

Copper Solution: Copper cabling is typically less expensive than fiber, both in terms of cable and associated hardware like switches and transceivers. However, maintenance and replacement costs can be higher due to copper’s susceptibility to interference and degradation.

Fiber Solution: Fiber optic cabling has a higher initial cost due to the need for specialized equipment and expertise. Despite this, fiber’s lower maintenance costs and longer lifespan can make it a cost-effective option in the long term.

- Use Cases

Copper Solution: Copper is ideal for short-distance applications such as local area networks (LANs), office wiring, and residential setups. Its flexibility makes it suitable for environments where frequent reconfiguration is necessary.

Fiber Solution: Fiber is well-suited for long-distance applications, backbone infrastructure, data centers, and environments requiring high-speed, high-capacity data transmission. It is also optimal for industrial and outdoor environments where electromagnetic interference is a concern.

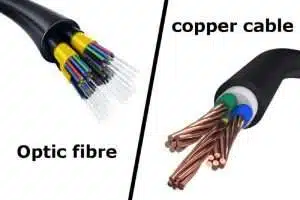

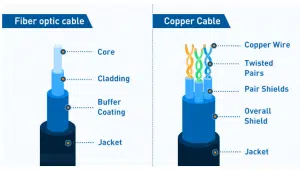

What are the main components of each one?

Copper Cables:

- Conductor: Copper wires

- Insulation: Polyethylene or PVC

- Twisting: Twisted pairs to reduce interference

- Shielding: Optional (STP or UTP)

- Outer Jacket: PVC or LSZH

Fiber Optic Cables:

- Core: Glass or plastic

- Cladding: Glass or plastic

- Buffer Coating: Protective layer

- Strength Members: Aramid yarn or similar materials

- Outer Jacket: PVC, LSZH, or polyethylene

- Additional Coatings: Optional environmental protections